A water cooled unit would have a lower specific power compared to an air cooled compressor which basically means you can expect it to be more efficient.

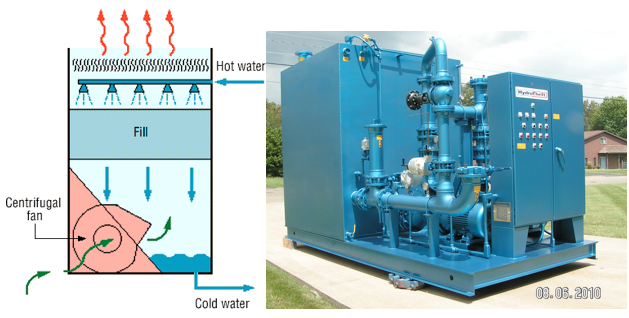

Water cooled compressor system.

The more compressed air is cooled inside a compressor s inter cooler and aftercooler the more energy efficient the compressor will be and the more the water vapor will be condensed a water cooled compressor installation puts little demand on the compressor room ventilation system as the cooling water contains in the form of heat approximately 90 of the energy taken up by the electric motor.

A variety of water cooled compressor sizes is available to match your particular application with delivery rates of 8 4 27 scfm 238 764 l min at up to 6000 psi 414 bar.

Water cooled chiller has advantages over air cooled chiller in terms of capacity efficiency life and environmental impact.

The most convenient efficient and effective way to cool your high pressure compressor.

With the same capacity as a pump driven water cooled system but with no pump no fan and vitually silent when running.

But you would also like to consider the electrical costs of the cooling system as well as the water and water treatment costs.

Water cooled chiller is a device used to remove heat and transfer it to the environment.

Water cooled air conditioner.

If you have a well ventilated spot to mount the compressor it is good to consider air cooled first.

Water cooled chillers are mostly used in air conditioning industry or any other specific places that require temperature control.

Excellent temperature regulation with adjustable thermostat.

You can compare specific performance values by looking at the compressors cagi data sheets.

Operates on 12 or 24 volts dc.

The multi stage industrial compressor units are suitable for intermittent and continuous.

Typically a water cooled compressor will have a slightly lower specific power kw 100 cfm than an air cooled compressor this means it s a bit more efficient.

Water is used to cool the hot air refrigerant 180 f or 82 c from the compressor by pumping counter flow water in the condenser.

Extend the life of your compressor by considering one of our sea or fresh water cooled compressor systems.

Bauer kompressoren builds durable and powerful two stage three stage and four stage water cooled high pressure compressors for specific free air delivery rates and pressures as well as five stage screw booster units.

Figures taken from a data sheet of a single stage lubricant cooled rotary screw air compressors at 100 psig pressure 8600 working hours and 70 f water temperature.

Air cooled is the simplest to install and very trouble free.

Jumbo compact systems combine large evaporators with efficient and powerful water cooled compressor units.

Powerful water cooled compressor unit is ideal for tropical climates large evaporators provide fast and even freezing.